2017 Engineering Excellence Awards

2017 Grand Conceptor

Tetra Tech Honored as Engineering Excellence Award "Grand Conceptor" For Chickasaw Nation "Inkana" Bridge

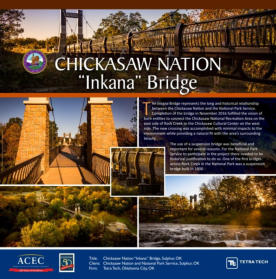

Chickasaw gathered their possessions, crossed the Mississippi River, and began their march on the Trail of Tears. More than 500 Chickasaw died on the trail before settling around the Arbuckle Mountains near Sulphur, Oklahoma. Today, much of this area is known as the Chickasaw National Recreation Area and is overseen by the National Park Service. Sulphur is historically known for its ‘healing’ springs visited by people from across the country. In 1906, the area become one of seven National Parks in the U.S.

In 2010, the Chickasaw Nation opened their Cultural Center to preserve their heritage and educate the Chickasaw people and the public about their persevering history. It became apparent that a vital link was needed between the Cultural Center and the National Park, so in 2016, a suspension bridge was constructed across Rock Creek for pedestrians to access both the National Park and the new Cultural Center.

To the minimize impact to the park, waterfalls, and Chickasaw grounds, a suspension bridge was determined to be an ideal solution.

The 195-foot, single-span suspension bridge incorporates several unique and innovative features. The towers were set on the outer banks of Rock Creek to minimize tree removal and to not disturb the waterfalls. A very open and slender Vierendeel truss design constructed of structural steel tube, with the tube ribs supporting the precast concrete deck panels was used so as not to distract from the area’s natural beauty.

Other special features include the ornamental handrails and the rock pattern on the towers that required a special concrete form liner.

The Southeast Indian spiral design and the National Park arrowhead symbol that are cast in the bridge tower cross beam represents the close relationship and cooperation between the Chickasaw Nation and the National Park Service.

The Chickasaw Nation named the new suspension bridge “Inkana”, which means friendship in the Chickasaw language.

2017 Honor Award Winners

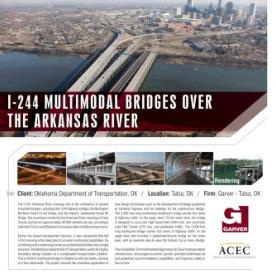

Garver - I-244 Multimodal Bridges of the Arkansas River

The I-244 Arkansas River crossing sits at the confluence of several important bridges, including the I-244 highway bridges; the Burlington Northern Santa Fe rail bridge; and the historic, abandoned Route 66 Bridge. The crossing is one of only four Arkansas River crossings in Tulsa County and serves approximately 80,000 vehicles per day, providing a vital role in Tulsa’s and Oklahoma’s transportation mobility and economy.

The bridges that were replaced in the project had reached the end of their service life and were classified as structurally deficient. The condition of the bridges was poor and required the Oklahoma Department of Transportation to spend approximately $1.1 million dollars annually in maintenance costs and lane closures to perform the repairs.

During the project development process, it was recognized that the I-244 crossing is the ideal place to provide multimodal capabilities. By combining and condensing numerous multimodal facilities into a single structure, the Oklahoma Department of Transportation put forth a highly innovative design solution to a complicated transportation problem. To provide a multimodal facility carrying highway, rail, and pedestrians over the Arkansas River, several design challenges had to be overcome. These challenges included designing around the multiple geometric constraints and providing rail capabilities at existing ground level with unknown ultimate configuration. In addition, the highway bridge had to be at an elevated level compatible with the existing interchange of the Inner Dispersal Loop, all while providing hydraulic adequacy, constructability, and maintaining existing traffic on this vital route.

The 3,300-foot long multimodal westbound bridge carries four lanes of highway traffic on the upper level. On the lower level, the bridge is designed to carry one High Speed Rail (HSR) line, one Commuter Light Rail Transit (LRT) line, and pedestrian traffic. The 3,000-foot long eastbound bridge carries four lanes of highway traffic on the upper level and includes a pedestrian bridge on the lower level, with an overlook area to view the historic Cyrus Avery Bridge. Both bridges incorporate aesthetics to commemorate Tulsa’s heritage with Route 66.

This is the first multimodal bridge in Oklahoma with two levels, and one of a few nationwide. The project required the innovative application of new design techniques and the project required a partnership between the Oklahoma Department of Transportation and stakeholders to solve the problem of how to replace these bridges.

The completed I-244 bridges improve Tulsa’s transportation infrastructure, encourages economic growth, provides multimodal rail and pedestrian accommodations capabilities, and improves safety in the corridor.

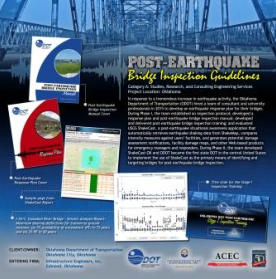

Infrastructure Engineers - Post Earthquake Bridge Inspection Guidelines

Recent studies and data collected by the United States Geological Survey (USGS) and Oklahoma Geological Survey (OGS) show that Oklahoma has seen a tremendous increase in the frequency of earthquakes since 2009.

From 1978 through 2008, only 50 magnitude 3.0 and greater earthquakes were recorded. From 2009 through 2013, 270 magnitude 3.0 and greater earthquakes were recorded, including three magnitude 4.0 to 4.8 earthquakes, and a magnitude 5.6. From 2014 through 2016, there were 2,111 magnitude 3.0 and greater earthquakes recorded, including 45 magnitude 4.0 to 4.8 earthquakes, and the largest earthquake in Oklahoma’s history – a magnitude 5.8 earthquake that occurred in Pawnee, OK on September 3, 2016.

When the earthquake activity began to increase, ODOT had to determine when and how to inspect their bridges after an earthquake. Their initial response was to inspect after every earthquake with a magnitude greater than 3.0. However, as time went on, they found this to be overly conservative. On January 23, 2015, ODOT changed the protocol to dictate that bridges must be inspected within a 5-mile radius (measured from the epicenter) for earthquakes with magnitudes from 4.0 to 4.9, within a 25-mile radius for earthquakes with magnitudes from 5.0 to 5.5, and within a 50- mile radius for earthquakes with magnitudes greater than 5.5. If damage was found within those radii, then the inspection radius was expanded by 5 miles. During 2015, 30 earthquakes triggered inspections under this protocol, yet no significant earthquake-related bridge damage was found. ODOT maintenance personnel were getting fatigued by the excessive number of inspections.

In 2015, ODOT hired a team of consultants led by Infrastructure Engineers, Inc., in partnership with The University of Oklahoma and Kleinfelder, to revise their post- earthquake bridge inspection protocol and develop a formal response plan. This project consisted of two phases: Phase I established an interim post-earthquake bridge inspection protocol that provides guidance for responding to seismic events; developed a field inspection manual detailing the procedures for field inspection of bridges by ODOT personnel and/or qualified bridge inspectors and/or first responders such as fire or public safety personnel in the aftermath of an earthquake; developed a first draft of the earthquake response plan; and developed materials and training for Level 1 and Level 2 inspections.

Phase II established a comprehensive post-earthquake bridge inspection protocol; developed the ShakeCast computer program that prioritizes bridges for inspection after a seismic event through interface with the USGS database; finalized the earthquake response plan; and developed management level training on the response plan.

Mead & Hunt - USACE Broken Bow Dam Diversion Tunnel

The United States Army Corps of Engineers (USACE) Broken Bow Dam Diversion Tunnel Investigation required non-destructive testing and a high level of hazard analysis and safety. The consultant team successfully completed the investigation by using advanced technologies and working closely with the USACE Tulsa District. Mead & Hunt and our teaming partners completed the investigation on the originally scheduled date, overcoming record amounts of rainfall.

USACE Tulsa District wanted to confirm the safety and stability of the dam’s diversion tunnel to ensure that operations could continue effectively without risk to staff or downstream life and property. Several challenges made for an interesting and complex project from the start. The upstream half of the tunnel is always flooded, and it was imperative that testing did not damage the project. The weather also had a say in the matter, which forced the team to be clever about coordination and adapt the approach to meet what turned into a challenging schedule.

In response to concerns regarding safety of the diversion tunnel and the low level outlet facility (LLOF) at the Broken Bow Hydroelectric Dam, Mead & Hunt and our teaming partners approached the investigation using only non-destructive testing to provide estimates of the critical geologic parameters and tunnel performance.

Hibbard Inshore’s underwater remotely operated vehicle (ROV) with synchronized video and sonar provided our team and the Tulsa District with the first look at the flooded portion of the 170-foot-deep diversion tunnel and the upstream gate structure since its original construction in 1973. The underwater inspection informed our structural and mechanical investigation, while sparing the effort, time and expense of dewatering the tunnel. Using historic records, photogrammetry and outcrop mapping, our geological sub-consultant, Terracon, provided an estimation of the rock mass rating (RMR) and rock quality designation (RQD) without drilling. This estimation, in turn, informed our structural evaluation.

Terracon used Schmidt Hammer and Windsor Probe concrete compressive tests and ground penetrating radar (GPR) to survey the downstream tunnel. This provided a very good analysis of the downstream concrete liner and its connection to the surrounding rock. By building finite element models of the upstream tunnel, gate structure and downstream tunnel, we were able to evaluate the performance of critical LLOF components against a range of conditions to include section loss and differing reservoir and ground water levels.

Because we used non-destructive testing, we only had estimates of the critical geologic parameters and tunnel performance. However, these estimates will still allow the District to proceed to a semi quantitative risk-assessment of Broken Bow Dam to be performed at a later date. Our extensive analysis will also allow the District to refine the estimates with only a few geological borings. This investigation will inform and justify future options that could include plugging the tunnel or constructing and installing a new bulkhead.

Burns & McDonnell - Stillwater Energy Center

The Challenge was to develop a flexible power source that would supplement renewable sources and create greater transmission grid stability.

During the 1950s, the Boomer Lake Station, a city-owned, 27-megawatt natural gas-fired steam turbine plant, generated most of the electricity needed by the community of Stillwater, Oklahoma. When demand exceeded the power station’s capacity, Boomer Lake Station was upgraded and converted to a peaking plant. By 2012, as the plant neared the end of its useful life, Stillwater Electric Utility (SEU) — the state’s largest municipal generator and transmission utility — faced a major decision: whether to rebuild Boomer Lake Station, construct a new, modern power plant or exit the power generation business altogether.

The Solution: design and construction of the Stillwater Energy Center, a new 56-MW reciprocating engine plant that provides a low-cost supplemental source of power generation.

As the Utility began to weigh its options, it realized there were other factors to consider. If it ceased power generation, for example, the company would become dependent on other energy sources and lose control of its energy assets, increasing its exposure to fluctuations in power pricing — an outcome owners preferred to avoid. Rebuilding Boomer Lake also posed challenges. Like other electric power producers, the utility was under pressure to rebalance its energy generation portfolio by adding more renewable sources to the mix. Additional wind and solar energy, however, would make the transmission system less stable — especially if these renewable sources were paired with a traditional plant like Boomer Lake Station, whose boilers were designed to run constantly at full output, and could not easily adjust to changes in the load.

Instead, SEU sought a new solution that could be brought online quickly, produce power efficiently and would be flexible enough to counterbalance fluctuating renewables. It found the answer in reciprocating internal combustion engines. These efficient engines can be brought online and to full load in less than 10 minutes, enabling them to respond quickly to energy fluctuations.

SEU retained Burns & McDonnell in 2014 to design a 56-MW power plant that used natural gas-fired reciprocating engine technology — the first of its kind in the Midwest. The power generation building at the new Stillwater Energy Center houses three Finnish-made 18-MW Wärtsilä engines. The project also includes an operations and administration complex and a new electrical transmission and distribution substation. The $70 million energy center is designed to “chase the wind” by ramping up or down in response to energy market fluctuations of Oklahoma’s Southwest Power Pool (SPP) Integrated Marketplace (IM). Today, it produces approximately double the energy created by Boomer Lake Station [at a significantly lower cost]. Designed for future expansion, the new Stillwater Energy Center is more than an economically sound source of energy for Stillwater’s current power needs. It also positions Stillwater to capitalize on future energy markets and helps support low-cost power to all public power customers in Oklahoma.

2017 Finalist Awards Winners

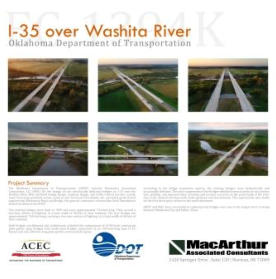

MacArthur Associated Consultants - I-35 over Washita River Bridges

The Oklahoma Department of Transportation (ODOT) selected MacArthur Associated Consultants, LLC (MAC) for the design of two structurally deficient bridges on I- 35 over the Washita River. MAC provided bridge design, roadway design, and traffic control services. Lemke Land Surveying provided survey services and Terracon Consultants, Inc. provided geotechnical engineering. Manhattan Road and Bridge, the general contractor, received the Deck Smoothness Award incentive from ODOT.

The existing bridges were built in 1969 and approximately 724-feet-long carrying a two-lane section of highway at a total width of 38-feet of clear roadway. According to the bridge inspection reports, the existing bridges were hydraulically and structurally deficient.

The new bridges are approximately 760-feet-long carrying a two-lane section of highway at a total width of 40-feet of clear roadway.

Both bridges, northbound and southbound, included the replacement of existing two (4-90-foot) continuous plate girder span bridges with multi-span bridges comprised of six 100-foot-long type IV PC Beams and one 200-foot-long plate girders at the middle spans.

ODOT and MAC were successful in replacing two bridges over one of the largest river crossing between Oklahoma City and Dallas, Texas.

Triad Design Group - I-40 & Radio Road Interchange

Recent energy industrial development east of El Reno has resulted in an increase of heavy equipment and delivery vehicles. Better access to these growing industrial areas was desperately needed. The Oklahoma Department of Transportation (ODOT) with support from local entities of the City of El Reno, Canadian County, and energy businesses, partnered in order to provide the much needed access improvements with a new interchange on I-40 at Radio Road. The new interchange was necessary in order to provide improved access to El Reno, as well as facilities such as Canadian Valley Technology Center, the OKC West Livestock Market, Chesapeake Energy, and numerous other businesses located along Radio Road and SH-66.

Several alternatives were considered during the preliminary design phase including variations of folded diamond and diamond interchanges in order to replace the existing grade separated Radio Road overpass. Every attempt was made to minimize the footprint while providing a safe, economical, and effective facility for the traveling public. Upon completion of the design report, a diamond interchange was selected which would minimize impacts to area wetlands and streams. The project included several RCB structures to convey an existing stream through the project. In addition, Triad’s team needed to work closely with ODOT Environmental Division, U.S. Army Corps of Engineers (USACE), and the Oklahoma Department of Environmental Quality (ODEQ) in order to reduce impacts to wetland, stream, and open water areas which were present within the project footprint.

Located two miles east of El Reno and eleven miles west of Yukon, the construction of the new interchange has already begun to add to the booming economic and population growth of Canadian County. The interchange and connecting improvements to Radio Road have ensured that the increase in overall traffic volumes especially the increase in large trucks and oil field equipment, have not adversely impacted traffic operations and safety along SH- 66, Jenson Road, as well as the other interchanges of the area.

Olsson Associates - Oklahoma City Zoo Parking Lot Improvements

Olsson Associates provided the preliminary engineering, design, construction documents, and construction administration services for the Oklahoma City Zoo Parking Lot Improvements Project. The $5 million project was constructed in a very short time frame beginning in late October 2016. Construction activities were scheduled during the winter months of 2016 and the spring of 2017 to take advantage of lower attendance rates and fewer parking needs. The design was sequenced to allow for partial use of the parking area throughout construction. Provisions were made to accommodate pedestrian traffic through the work areas. The majority of the project was completed in June 2017 in time for summer crowds.

The project scope included the reconfiguration of existing parking lot aisles, the addition of a right-in and right-out entry/exit along Remington Place, the widening of Remington Place to accommodate an eastbound right turn lane, the relocation of bus passenger drop-offs and pick- ups from the front to the west zoo entrance, a secondary entrance pavilion, pedestrian facility improvements at the main parking lot and overflow parking lot at Remington Park, lighting, and landscape improvements.

This project improved vehicular, bus, and pedestrian traffic in the main parking lot; pedestrian traffic from overflow parking at Remington Park; and aesthetics and landscaping throughout the project area. These improvements provide a safer, more efficient, and more inviting experience for guests as they enter the zoo.

CEC Corporation - KFOR-TV Tribune Media

In 1949, WKY-TV, which is now known as KFOR-TV, was the first television station to sign on the air in Oklahoma. Shortly after coming on air, they moved into their existing facility. Over the years, there have been many additions and remodels to the existing building, along with changes in technology that pushed the old building to its limit. KFOR-TV and their sister station KAUT-TV (both owned by Tribune Media) were in need of a new facility that was modern, flexible, and able to withstand the Oklahoma weather.

The new building was sited to be on the same property on which the existing facility is located. This allowed for many existing utilities and satellite network connections to be utilized from the existing building. It also created site congestion and phasing problems. The existing building was required to be in full operation until the new building was finished. Once construction reached substantial completion, the TV stations simultaneously, and nearly instantaneously, switched to broadcasting from the new studios.

In order to serve central and western Oklahoma, the building was designed to resist winds associated with an EF3 tornado. This allows the news teams to focus on the needs of the general public while knowing they would be safe in the facility. An exterior precast concrete covered parking area was also included in the project to allow the news teams to protect their property while they are doing their jobs. CEC provided the Structural Engineering and Civil Engineering consulting services for the project. Team members included; REES Architects, Alvine Engineering serving as the MEP Consultant, and Howard-Fairbairn Site Design, Inc. serving as the landscape architect.