2018 Engineering Excellence Awards

2018 Grand Conceptor

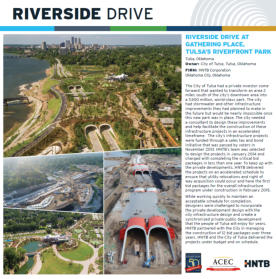

HNTB Corporation Honored as Engineering Excellence Award "Grand Conceptor" Riverside Drive at Gathering Place, Tulsa

The City of Tulsa had a special problem to work through. A community foundation wanted to create an amazing $465 million park, along the Arkansas River in Tulsa, Oklahoma, between 41st Street and 21st Street, less than 2 miles from the downtown business district.

The park, dubbed a “Gathering Place,” would be transformational for the city and the region. However, the city had infrastructure issues in the area, such as stormwater flooding, aging infrastructure, inadequate water and sewer lines, and a busy arterial street with significant safety concerns from chronic speeding, geometric deficiencies, and roadside safety issues. City leadership knew that it was critical to establish a foundational infrastructure system to support the park and it needed to happen in a timely and cost effective manner.

Often the schedule for privately funded projects moves faster than publicly funded projects. The privately funded park had a head start on the public infrastructure already, plus the city needed to determine how to fund $41 million of critical infrastructure improvements. HNTB Corporation (HNTB) started civil, utility, bridge and electrical design work for the park in 2012. However, it was November 2013 before the city passed their tax-funded bond initiative. They needed a firm that could perform quality work in a short timeframe to catch up with the park. The city hired HNTB in February 2014 and challenged the firm to accelerate design of the infrastructure improvements to be ready for construction by the end of the year.

The city broke ground in early 2015 with the first two projects of an eventual 10 bid packages. The first six critical projects were under construction within the year.

In addition to overseeing and working alongside the city to coordinate all utility relocations and right of way acquisitions, HNTB’s responsibilities also included coordinating with another primary stakeholder, George Kaiser Family Foundation (GKFF), and the development team for the Gathering Place park.

The $400 million in private donations for the park brought extreme scrutiny and stakeholder engagement requirements to the city’s infrastructure projects. Full construction of the park and supporting infrastructure took three years, and anxious residents and businesses watched with interest and amazement as the old Riverside Drive and undeveloped floodplain morphed into land bridges, skate parks, landscaped green ways and more. What once was a mundane, forgettable stretch of road was becoming a place where friends could gather, families could play and visitors would envy as a truly beautiful and functional part of the city.

The Gathering Place and Riverside Drive re-opened fully in September 2018 and Tulsans were able to experience this world-class park and first-class roadway combining to make this stretch of Tulsa’s Arkansas Riverfront truly unique. HNTB and the City of Tulsa delivered the city’s bond and sales tax projects under budget and achieved fantastic results.

2018 Honor Award Winners

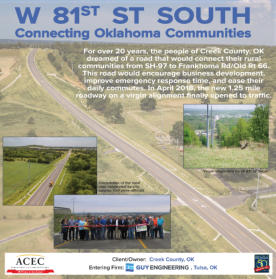

GUY Engineering Services - West 81st Street South, Creek County, OK

Frankhoma Rd is the most travelled road in Creek County District 2, with a busy industrial park located 0.5 miles east of the W 81st St South intersection. But economic development in the area was hampered by the lack of a roadway connecting Frankhoma Rd to SH-97 just 1.25 miles away.

The plan to extend 81st St from Frankhoma Rd to SH-97 was delayed for 20 years by funding issues and by a remapping of the county commissioner districts. In 2010, GUY Engineering (GUY) received a Notice to Proceed on the project design, and in early 2018, the new, long-awaited road opened to the public.

Addressing the challenges of steep terrain and multiple land uses, GUY developed an alignment that minimized impacts to property and overhead transmission lines. Public meetings allowed property owners and other interested parties to provide input. GUY also coordinated with the ODOT Rail Division for an at-grade rail crossing agreement.

The 1.25 miles long curbed roadway consists of 2 12-ft lanes with a continuous 16-ft left turning lane. A storm sewer system was included in anticipation of future development. The Frankhoma Rd intersection and approaches were also reconstructed and raised approximately 6.0 ft, for compatibility with the BNSF crossing elevation.

Creek County wanted this roadway in order to reduce travel time for drivers and increase development opportunities in the area. The completed project successfully fills both of these needs. In addition, the improved access provided by this roadway improves emergency vehicle response time for area residents.

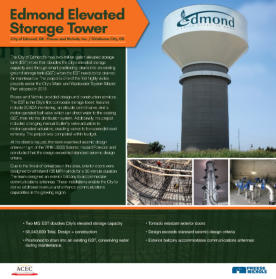

Freese and Nichols - Edmond Elevated Storage Tank, Edmond, OK

The City of Edmond’s new, two-million gallon elevated storage tower (EST) more than doubles the City’s elevated water storage capacity and, through smart positioning and re-purposing, drains into an existing ground storage tank when the EST needs to be flushed. The project is one of the first constructed as part of the City’s Water and Wastewater System Master Plan adopted in 2013.

Freese and Nichols provided design and construction services. The elevated storage tower is the City’s first composite storage tower and includes SCADA monitoring, an altitude control valve, and a motor-operated ball valve which can be used to direct water to the existing ground storage tank and ultimately into the distribution system.

Additionally, the project included changing the existing manual butterfly valve actuators to motor-operated actuators. This will reduce staff travel time to the site by allowing valves to be opened/closed remotely. The project was completed within budget with a Construction Cost (Budgeted and Actual): $5,893,000.

Garver - Water Reclamation Facility Phase 2 Upgrades, Norman, OK

The Norman Utilities Authority (NUA) has long been an advocate of environmental stewardship and has led the state in the implementation of sustainable solutions to maintain proper water quality and environmental health. The award-winning utility was the first in Oklahoma to install a yard composting service, and their hard-working operations staff kept the City’s aging wastewater treatment plant (WWTP) operational and functional for more than twice its original estimated life cycle.

By 2010, however, some of the treatment processes at the WWTP had been in operation for more than 50 years, and Norman’s burgeoning population — it is now the third largest city in the state — routinely consumed up to 90 percent of the existing capacity. With the receipt of a compliance schedule to incorporate new regulatory disinfection requirements, the Authority decided to embark on an ambitious overhaul of the facility to address all of these issues, transforming it from a 12 MGD WWTP into a 17 MGD Water Reclamation Facility (WRF) to better serve the citizens of Norman.

Given Garver’s historical plant knowledge, local access, and national expertise, the City selected Garver for the study phase of the program, which identified more than $100 million in capital improvements. Garver performed a comprehensive audit and evaluated ways to improve the facility’s operations, address aging infrastructure, comply with future potential permit requirements, and accommodate increasing flows. At the conclusion of the study phase, Garver helped NUA and the City prioritize alternatives. Garver was then selected for the design and construction phase, which included improvements to increase treatment capacity, enhance operational reliability, and address new effluent discharge requirements. Specifically, Phase 2 of the project provided enhanced screening operation, advanced flow split with peak flow bypass, primary clarification rehabilitation, additional biological treatment capacity with high-efficiency turbo blowers, secondary clarification, RAS/WAS pumping with variable frequency drive (VFD) controls, post aeration, a new parallel 66-inch outfall line, odor control, solids thickening, and anaerobic digestion. To address new effluent discharge and redundant power supply requirements, new UV disinfection/post aeration facilities and site-wide backup power were installed. The addition of UV disinfection to the plant has also allowed NUA to maintain new year-round disinfection requirements, and improvements to the headworks facilities make it possible for fewer operators to maintain plant operation during major storm events.

Garver helped the City realize cost savings through utilization of some of the plant’s existing infrastructure and regulatory variance approval from the Oklahoma Department of Environmental Quality (ODEQ). During the design phase, Garver conducted multiple workshops with operations staff involvement, which helped alleviate future operations and maintenance concerns.

Taking into consideration the size and complexity of the Norman WRF Phase 2 Upgrades, Garver worked with NUA to prequalify potential contractors to promote successful execution and project delivery. Garver also provided on-site observers during construction who were able to identify potential issues and successfully coordinated solutions that minimized the number of change orders. With the receipt of highly favorable bids from the pool of contractors as well as tight budget control during construction, NUA had the opportunity to add multiple features to the project scope. Garver worked with the contractor to refine the additional plans, thus saving time and money by streamlining the process.

This project represented the largest capital improvement project in the history of the City of Norman and was the largest Oklahoma Clean Water State Revolving Fund (CWSRF) loan at the time of award. Since February 2017, NUA has not reported any permit violations, and the high-quality effluent discharge is well below the permit limits for allowable pollutants.

C P & Y, Inc. - Hefner Water Treatment Plant Sludge Handling Facility, Oklahoma City, OK

Oklahoma City Water Utilities Trust (OCWUT) was in need of an innovative solution for the processing of lime sludge produced as part of the water purification of drinking water at the City’s Hefner Water Treatment Plant (WTP). Prior to the construction of the Hefner Solids residuals project the City owned and operated a lagoon system for lime sludge with a maximum capacity of 100 million gallons per day (MGD). Due to the high costs to maintain the lagoons, the land locked location of the plant, and the operational issues experienced as plant flows approached 75 MGD, the City was looking for a solution that would allow for the abandonment of the lagoons.

Through an initial evaluation of multiple dewatering alternatives at the plant it was determined that converting to a belt filter press mechanical dewatering system was the best solution when treatment capacity was expanded to over 100 MGD. Attempting to maintain the current lagoon system had a 30-Year NPV of approximately $82 million while the selected mechanical dewatering alternative had a 30-Year NPV of approximately $62 million. The mechanical dewatering system is designed for a water treatment flow of 150 MGD with the ability to be easily expanded to 200 MGD in the future.

To implement the belt filter press mechanical dewatering solution the following improvements were designed and constructed: lime sludge pump station to transport the clarifier blowdown to the solids handling area, two gravity thickeners to further thicken the solids, two balancing tanks to equalize the flow, lime sludge recirculation and sludge feed pump station, belt filter press solids handling building, polymer feed system, recovery pump station, associated electrical gear, and truck loading and solids storage area. While the main focus of the project was addressing increasing lime sludge as treated flows increased, the projected also provided additional bolstered systems. First, the Solids Pump Station responsible for pumping clarifier blowdown was changed to a dry pit pump station from a submersible pumps station to allow for easier operation and maintenance. Secondly, the Recovery Pump Station was replaced allowing for a return rate of filter backwash water of 15-20% of the treated water flow at a production rate of up to 150 MGD. Finally, new heavy duty concrete paving and a second connection for the plant water loop were provided to ensure trouble free operations of the plant for years to come. The total project construction was approximately $35.5 million.

2018 Finalist Awards Winners

Garver - Pig Farm Road Low Water Crossing Improvements, Ft. Sill, OK

Fort Sill plays a vital part in the training of U.S. Army Troops. However, there was an issue that prevented them from being able to fully prepare these troops for their duty to serve our country. Seemingly every time it rained, the East Cache Creek would flood Pig Farm Road and make one of the key training ranges inaccessible to trainees.

This is when Garver, LLC (Garver) was called upon to design a new low water crossing in order to provide better drainage and the ability to safely reach the training destination at Fort Sill.

Garver, as Designer of Record, led the planning, design, and construction administration services of a five-cell, 20-foot by 15-foot reinforced concrete box culvert with headwalls, wingwalls, and aprons to replace the existing insu?cient low water crossing. This new crossing was designed to allow for two-way tra?c, providing a more e?cient flow of tra?c both to and from the training ranges. The new raised roadway was also designed to pass up to a 25-year storm without overtopping.

The new crossing and its associated components were specifically designed to be capable of supporting their own weight and the weight of the heavy and frequent military vehicles that utilize the crossing daily.

Garver’s design provided a new crossing, which was elevated nearly 20-feet above the existing crossing, along with slope and embankment protection in order to prevent the erosion of the embankment, road, and culvert during a 100-year flood event. The design and construction of the new crossing provides the installation with the comfort of knowing the training ranges can be accessed and utilized year round without being impeded by flood waters.

MacArthur Associated Consultants - Iowa & Dakota Streets Residential Street Improvements, Norman, OK

The City of Norman selected MacArthur Associated Consultants, LLC (MAC) to provide professional engineering consulting and design services for Dakota Street and Iowa Street from Berry Road to University Boulevard.

The purpose of the project was to replace the aging pavement and to improve the poor drainage along the two streets. The existing roadway consisted of both asphalt and concrete sections with shallow ditches and intermittent storm sewer. The improved roadway is an asphalt section with curb, gutter and concrete intersections. MAC provided a hydraulic and hydrologic analysis of the drainage basin and the design of a new storm sewer system. Other improvements included ADA ramps at major intersections and grading that allows for future sidewalks.

The drainage for this project posed unique challenges. The terrain is flat, and the flowlines of the existing storm sewers were shallow. Our team improved the vertical profile in a way that introduced longitudinal slope for drainage purposes. This provided positive drainage from each residence towards the street, in return lowering the profile. Maintaining the existing drainage patterns was a focal point of the project, so as to not overload either one of the existing sewer mains that drain the corridor. The City of Norman chose to use the ADS Nyloplast Storm Sewer System for construction, as opposed to the traditional (ODOT) standards and specifications. The Nyloplast System is less expensive and results in a quicker installation, perfect for this type of project.

The initial project began in February 2015. The first set of final plans, specifications and estimates were submitted to the City of Norman in March 2016. The project was initiated with a very constrained budget due to the limited funding sources. Unique contracting methods were employed when it was discovered that traditional contracting methods would not allow the project to remain within budget. The City opted to use a mix of internal forces and contractors for specific individual tasks. The initial three phases were further separated into nine individual projects, each one managed and overseen by the City staff.

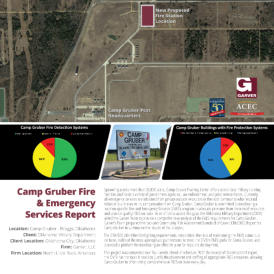

Garver - Camp Gruber Fire & Emergency Services Report, Camp Gruber, OK

Located 14 miles southeast of Muskogee, Oklahoma, the Camp Gruber Training Center covers more than 33,000 acres and offers world-class military training ranges and facilities. Currently, all emergency services are obtained from private outside services from the local community who respond voluntarily and receive no compensation for their services from Camp Gruber. Camp Gruber is committed to developing a location-specific Fire and Emergency Services (F&ES) program to alleviate pressure from these local emergency services and provide quality F&ES to the installation.

In an effort to assess this goal, the Oklahoma Military Department (OMD) asked the Garver Team to provide a comprehensive analysis of the F&ES requirements for the installation. This involved assessing the level of risk within the Camp Gruber Training Center community and weighing the risks associated with current and proposed alternative response capabilities. The Garver Team prepared the two-part Community Risk Assessment/Standard of Cover (CRA/SOC) report for Camp Gruber to summarize the results of the analysis.

The CRA was completed to identify firefighting requirements and determine the levels of risk in Camp Gruber’s operational program. The CRA assessed Camp Gruber’s F&ES mission in six major functional areas: 1) the structure and number of firefighting companies employed at Camp Gruber; 2) the total elapsed time for response of suppression forces to a given incident; 3) wildland urban interface; 4) HAZMAT; 5) technical rescue and confined space rescue; and 6) fire prevention.

The second part of the report, the SOC, was completed to safeguard the effectiveness and efficiency of establishing the Camp Gruber F&ES as well as fire suppression operations, emergency medical services, and special operations delivery in protecting the personnel working or training on Camp Gruber. The Garver Team analyzed multiple factors as part of the SOC, including community profiles, installation risks, facility life safety requirements, fire-scene tasks, and service delivery performance standards set forth by the Army. The analysis of all these factors led to the justification and exploration of options for staffing the planned F&ES resources as well as detailed response plans to handle the risks these resources are expected to face.

This project was submitted to OMD more than four weeks ahead of schedule. With the completion of this important report, the OMD and Camp Gruber have the tools they need to justify the placement and staffing of appropriate F&ES resources on base, which will offer timely, comprehensive emergency response services.

MacArthur Associated Consultants - SkyWest Airlines Maintenance Facility, Oklahoma City, OK

In 2017, SkyWest Airlines selected Will Rogers World Airport (WRWA) in Oklahoma City to build their newest state-of-the-art maintenance facility bringing over 100 new jobs for maintenance professionals and potential for more. The new maintenance facility is 135,000 square-feet, accommodates up to nine regional aircraft, and supports overnight maintenance for its four major airline partners. Mike Thompson, SkyWest Airlines Chief Operating Officer, said “SkyWest Airlines selected Oklahoma City because of its location, competitive costs, and connectivity throughout our operation.”

SkyWest Airlines selected McAlvain Companies, Inc. (McAlvain) to manage the design and construction of the new hangar with an 18-month schedule. McAlvain selected MacArthur Associated Consultants, LLC (MAC) to provide professional civil engineering services due to MAC’s experience and knowledge of Will Rogers World Airport, air spacing issues and solutions, airfield and site design, ability to mitigate 404 issues with the U.S. Army Corps of Engineers (USACE), and ability to meet an accelerated schedule. MAC’s services included aviation planning and air spacing, survey, site design, utility relocation and coordination, permit coordination with the City of Oklahoma City and USACE, and construction administration.

This project had an accelerated schedule due to SkyWest needing to be in the hangar by June 2018. MAC received notice-to-proceed in March 2017 and provided a rough grading and utility package on May 17, 2017. The schedule was further complicated by a “blue-line” creek channel that had to be mitigated through the Tulsa District – USACE. In addition, the City of Oklahoma City Stormwater Department underwent a staff change bringing with them new requirements. Even with these hurdles, the team was able to get SkyWest into their facility by August 2018.